Updated: August 18, 2022

To provide you with the most accurate and up-to-date cost figures, we gather information from a variety of pricing databases, licensed contractors, and industry experts.

Many homes are underinsulated or could use additional insulation to make them more efficient, according to Energy.gov. Lacking insulation leads to higher energy bills and less comfortable living spaces. While insulation is easiest to add to a new home, there are ways to add insulation to existing spaces. One of the most common methods is blown-in insulation.

Blown-in insulation uses loose material that can be blown into cavities, such as walls or attics. It is less expensive and invasive than spray foam insulation and can often reach tighter areas than batt insulation. It comes in several materials and can be added in varying thicknesses and densities, leading to a wide range of costs.

The national average cost for adding blown-in insulation to a home is $3,000 to $7,000. Most people pay around $5,000 to fill wall cavities and the attic with cellulose insulation in a 2,000 sq.ft. home with a 2-car garage. This project’s low cost is $900 for blown-in cellulose in garage walls only. The high cost is $9,000 for varying insulation types in the wall cavities, area around the ductwork, attic, garage, and crawlspace in a 3,000 sq.ft. home.

Cost to Install Blown-In Insulation

| Blown-In Insulation Prices | |

| National average cost | $5,000 |

| Average range | $3,000-$7,000 |

| Low-end | $900 |

| High-end | $9,000 |

2022 Notice: How the Pandemic Impacted the Insulation Industry

The construction industry, like many others, has been significantly impacted by the Covid-19 pandemic. Labor shortages, supply chain problems, and a housing boom have led to an overall increase in construction costs of 4% to 7%. In particular, insulation has also been impacted by supply chain issues and shortages, causing the cost of insulation to rise 17% over the last year. Blown-in insulation is a popular material for those building new homes and those remodeling to help lower energy costs. This means that with the current rate of new construction, you may see further increases in costs and delays as time goes on. So, if you are considering adding insulation to your home, it is recommended that you do so soon to help lock in costs before they rise again.

What Is Blown-In Insulation?

Blown-in insulation is a loose-fill material blown via machine into otherwise uninsulated cavities. Blown-in is one of the many material types that can be used to insulate a home. It comes in three basic types - fiberglass, cellulose, and rockwool. Cellulose can be further broken down into two categories - wet spray and dense pack. Wet spray cellulose is the only material you can use when blowing it into your walls. The other materials can be used in attics, crawlspaces, basements, ducts, and other hard-to- insulate areas.

Blown-in is fairly fast and easy to apply. It can be added to existing homes more easily than batts or spray foam. It is more difficult to use in new construction, but fiberglass, rockwool, and dense-pack cellulose work in areas like attics.

This type is attractive because it fills existing cavities and hard-to-reach areas. You can fill the walls in an existing home by drilling small holes in the exterior walls and feeding the insulation in. This is much less invasive than other types, making it less expensive and faster. It can be added to many depths, so you can get a range of different insulating values, depending on where you apply it.

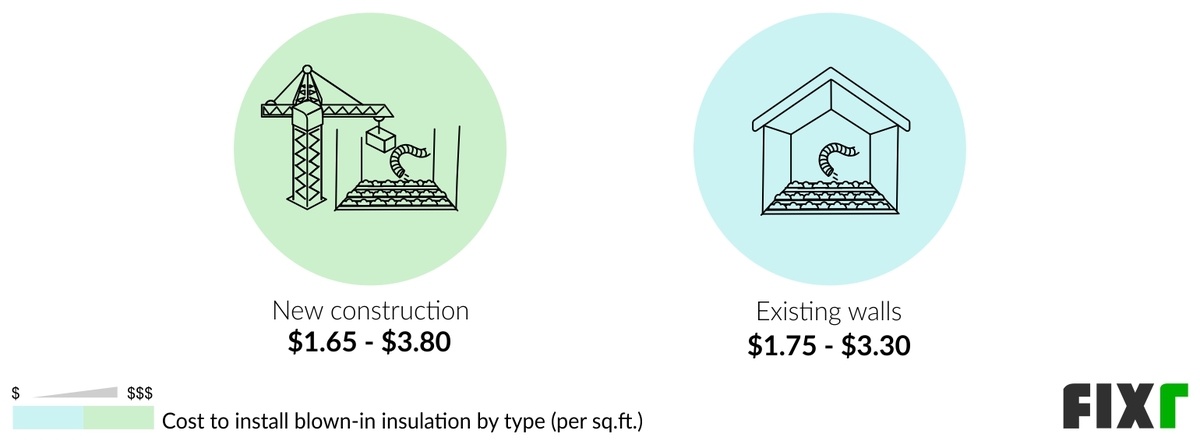

Blown-In Insulation Cost by Type of Installation

Most blown-in insulation is added to existing homes. The material means it is easier to blow it into existing spaces, adding it to places that batts or spray foam have a hard time reaching. You can use it in some areas of new construction. While the labor cost does not change radically for different installations, the material type does. Existing walls can only be filled with wet spray cellulose, while other areas use fiberglass, dense-pack cellulose, or rockwool - regardless of whether they are in a new home or a different area of an existing home. So, your costs vary by installation type because the material you choose varies more.

| Type of Installation | Average Costs per Sq.Ft. (Installed) |

| New Construction | $1.65 - $3.80 |

| Existing Walls | $1.75 - $3.30 |

Blown-In Insulation in New Home Construction

The cost of using blown-in insulation in new home construction ranges from $1.65 to $3.80 a square foot. It is typically not used everywhere in a new home. This is because it is faster and easier to insulate using different types to the walls before the walls are closed. The cavity must be sealed first to add blown-in to a wall cavity. However, you can add different types of blown-in to attics, crawl spaces, and other areas in new construction. This also means you are not as limited in options, and you can mix types in different spaces in new construction for the best results.

Blowing Insulation Into Existing Walls

The cost to add blown-in insulation to existing walls is $1.75 to $3.30 a square foot. The only type of blown-in that works in existing wall cavities is wet spray cellulose. This is the only type that can be applied to a vertical cavity because the dampened cellulose sticks and fills the cavities evenly. Small holes are drilled on the exterior of the walls to add the material. The material is blown in, and the holes are filled. You can color match the filled holes with most types of siding to disguise their appearance.

Cost of Blown-In Insulation per Square Foot

The cost of blown-in insulation averages $1.65 to $3.80 a square foot. Total costs vary due to how many inches of insulation, material, and where it is going. Typically, in-wall can only use about 5 inches of material at once, but you can use up to 18 inches of material on an attic floor. So, the total cost of an attic floor installation in a new house is greater than the cost of an exterior wall in an existing house.

| Size in Sq.Ft. | Average Cost (Installed) |

| 100 sq.ft. | $165 - $380 |

| 200 sq.ft. | $330 - $760 |

| 300 sq.ft. | $495 - $1,140 |

| 400 sq.ft. | $660 - $1,520 |

| 500 sq.ft. | $825 - $1,900 |

| 1,000 sq.ft. | $1,650 - $3,800 |

| 1,500 sq.ft. | $2,475 - $5,700 |

| 2,000 sq.ft. | $3,300 - $7,600 |

| 2,500 sq.ft. | $4,125 - $9,500 |

| 3,000 sq.ft. | $4,950 - $11,400 |

Average Cost of Blown-In Insulation by Material

Three materials create blown-in insulation - fiberglass, rockwool, and cellulose. Cellulose can be broken down into two types - wet spray, which is used in vertical applications and exterior walls, and dense pack, which can be used in attics, crawlspaces, and other open areas. Each material has costs, pros, and cons to consider.

| Material | Average Costs per Sq.Ft. (Materials Only) |

| Fiberglass | $0.50 - $1.10 |

| Wet Spray Cellulose | $0.60 - $1.80 |

| Rockwool | $1.40 - $2.10 |

| Dense Pack Cellulose | $2 - $2.30 |

Blown Fiberglass Insulation

The cost of blown fiberglass ranges from $0.50 to $1.10 a square foot. Fiberglass is made of spun fibers coated in glass. The material creates many air pockets to achieve good insulation. Fiberglass is inexpensive but most commonly used in batt form. It can be blown in on attic floors, crawl spaces, and other semi-open areas. It is naturally flame-retardant and does not require additional chemicals. It is not impacted by moisture like some other materials.

Wet Spray Blown Cellulose Insulation

The cost of wet spray blown cellulose is $0.60 to $1.80 a square foot. This is cellulose that can be blown into wall cavities or used in vertical applications. It is slightly dampened, sticking and settling better in vertical applications than other types. Cellulose contains a high concentration of recycled material, making it an attractive green option. The material is treated to resist insects and make it flame-retardant, but the chemical treatments may emit VOCs. Cellulose also becomes very heavy if you have a water leak because it absorbs moisture.

Blown Rockwool Insulation

The cost of blown rockwool ranges from $1.40 to $2.10 a square foot. Rockwool or mineral wool is made from spun silica. It is tougher and denser than cellulose or fiberglass, is naturally flame-retardant, and does not need to be treated. It is also more resistant to moisture than cellulose. It has a higher R-value or insulating value per inch than fiberglass but not as high as cellulose. This is a good material for using in areas like crawlspaces and some attic floors.

Dense Pack Blown Cellulose Insulation

The cost of dense pack blown cellulose averages $2 to $2.30 a square foot. This is a much thicker and heavier cellulose type than the type in wall cavities. It is not dampened before blowing, so it cannot be used in vertical applications. It is made of plant-based materials, including recycled paper, and treated to resist insects and make it flame-retardant. It has a better insulating value than other blown-in types. It makes a good choice for attics and attic floors.

How Many Bags of Blown-In Insulation Will You Need?

All blown-in insulation is sold in bags. The number of bags needed to complete a job varies, depending on the square feet you need to cover and the depth. The deeper, the higher the material’s R-value or insulating factor.

Blown-in insulation depths vary by area. The number of bags you need also varies by area. Below are the approximate number of bags you need to cover a 1,000 sq.ft. area at various depths. Several things impact the number of needed bags, from the material to the space’s layout.

| Depth of Material | Number of Bags |

| 5 Inches | 7 - 8 |

| 10 Inches | 14 - 15 |

| 15 Inches | 24 - 26 |

| 18 Inches | 28 - 30 |

| 20 Inches | 31 - 33 |

What Is the R-Value of Blown-In Insulation?

R-value measures how well a material resists thermal transfer. The higher the number, the better job it does at insulating. Most materials are given an R-value at 1 inch of thickness. The thicker the amount of material, the better the total R-value. Below are the R-values for each cellulose type when measured at 1 inch in depth.

| Material | R-Value |

| Fiberglass | 2.5 - 3.5 |

| Rockwool | 3.0 - 3.7 |

| Cellulose | 3.2 - 3.7 |

Blown Fiberglass R-Value

The average R-value of fiberglass insulation is 2.5 to 3.5 per inch. Blown fiberglass has a lower R-value than rockwool and cellulose. However, fiberglass has other benefits to consider. It naturally resists insect activity and is flame-retardant, meaning it is not treated with other chemicals and counts toward a healthy home material. Fiberglass is also one of the least expensive materials. It does not shift as much as heavier materials or become saturated with water, meaning it does not lose as much R-value over time like other materials.

Blown Rockwool R-Value

Rockwool has an average R-value of 3.0 to 3.7 per inch. This gives it a slightly higher R-value than fiberglass. Rockwool does not require chemical treatments to make it resistant to flame or insects. However, it can give off silica dust when blowing. This can cause health concerns for the installers and anyone in the area when it is being blown in. Therefore, this material should only be handled by professionals who understand the steps to keep themselves and others safe on the jobsite. Once installed, rockwool does not present health concerns for the people living in the home.

Cellulose Insulation R-Value

The average R-value for cellulose is 3.2 to 3.7 for an inch of material. Cellulose is the most common material. When dampened, it can be blown into wall cavities and other vertical applications. It can also be applied to attic floors, crawl spaces, and other spaces. Cellulose must be treated to make it flame-retardant and prevent insect activity. It can emit VOCs and is not seen as healthy as fiberglass.

Blown-In Insulation Cost by Brand

Several manufacturers make blown-in insulation. Some brands make a few types, while others only make one. Each has attributes to consider that may make one the right fit. Below are popular brands and the average cost of their material per square foot.

| Brand | Average Costs per Sq.Ft. (Materials Only) |

| Greenfiber | $0.30 - $0.60 |

| Owens Corning | $0.30 - $0.60 |

| Applegate | $0.50 - $1.50 |

| Nu-Wool | $1.30 - $4 |

| American Rockwool | $1.75 - $2.50 |

Greenfiber Blow-In Insulation

The cost of Greenfiber blown-in insulation is $0.30 to $0.60 a square foot for the material. Greenfiber makes cellulose insulation. They use roughly 85% recycled content in their products, making them one of the greener solutions for a home. They have several product lines to choose from. Some are for wall and vertical applications, while others are better for areas like attics. Their products are treated to be fire-resistant, and most are low-dust.

Owens Corning Blown Insulation

The material cost of Owens Corning blown-in insulation averages $0.30 to $0.60 a square foot. Owens Corning is one of the oldest manufacturers, dating back to the 19th century. They specialize in fiberglass and make all types, including blown-in. Their blown-in product is known as AttiCat. This is an expanding fiberglass designed to fill crevices and gaps in many areas in the home. It is self-feeding, so the installer only has minimal contact with the fiberglass.

Applegate Insulation

Applegate blown-in insulation ranges from $0.50 to $1.50 a square foot for material costs. Applegate makes several cellulose types, including various types of blown-in. Their material contains at least 85% recycled content. They also treat their products to be insect-resistant and flame-retardant. Their material exceeds most regulations for flame resistance, making it a safer for homes. They have dense-packed and damp-sprayed cellulose so that it can be used in different places.

Nu-Wool Insulation

Nu-Wool blown-in insulation costs $1.30 to $4 a square foot for the material. Nu-Wool has been making eco-friendly products since 1949. They produce cellulose made primarily of recycled content. Their material is Class-A fire rated and has been treated to prevent insect activity and fungus growth. Their materials are designed for professional and DIY installation. For DIY, they recommend batts rather than blown-in.

American Rockwool

The material cost of American Rockwool blown-in insulation ranges from $1.75 to $2.50 a square foot. American Rockwool specializes in rockwool. Their material is made from recycled blast furnace slag and trap rock. They make several lines, with their Rockwool Premium Plus being designed for residential use. The material is non-combustible and non-corrosive. It is designed not to settle as other loose types do.

Labor Cost to Blow In Insulation

The labor cost to install blown-in insulation averages $1.15 to $1.50 a square foot. Costs vary by access to the area and geographic region. Labor for this project is fairly simple but time-consuming, accounting for the costs. Insulating even a small area may take 3 to 4 hours, and the hose must be controlled by hand. While the installation is not difficult, it is labor-intensive. This means labor makes up the bulk of the cost. In a 2,000 sq.ft. installation, labor is roughly $2,300 to $3,000 out of the $3,000 - $7,000 average.

Cost to Install Blown-In Insulation by Location

Many places in the home may have blown-in insulation installed. Each area may require different thicknesses, meaning you have a range of costs per area. The following costs are broken down by location, assuming an average size for each space, with the average recommended thicknesses for each area.

| Location | Thickness of Material | Average Costs (Installed) |

| Ductwork | 3” - 5” | $400 - $1,000 |

| Garage Attic | 10” - 15” | $600 - $2,000 |

| Crawl Space | 8” - 18” | $900 - $3,000 |

| Attic | 8” - 18” | $1,750 - $5,500 |

| Walls | 3” - 5” | $2,000 - $4,000 |

Blown Insulation Over Ductwork

The cost of blown-in insulation over ductwork averages $400 to $1,000. The amount you ultimately use varies from a few inches to as much as 12 inches, depending on the height of the ducts and how deep you are covering the attic or crawl space the ducts are located in. However, you cannot directly install blown-in over ductwork. First, a second vapor barrier must be installed over the ducts. Then, a layer of spray foam is applied to the ducts. Finally, use blown-in for the final layer. This is done because of the temperature difference between the ducts’ inside and exterior. This difference causes the ducts to sweat. Without a second vapor barrier and spray foam insulation, you could have serious moisture problems if the ducts were covered only in blown-in.

Blown-In Insulation Above a Garage

The cost to install blown-in insulation in the attic space above a garage is $600 to $2,000. This space typically needs between 10” and 15” of insulation, depending on the climate. These costs assume the garage has average 2-car dimensions, and the space above the garage is unused or used for storage. When insulating above a single-car or larger garage, your costs could be different. Insulating above a garage keeps the space below more comfortable. This can also reduce energy bills if you heat and cool your garage.

Blown Insulation in a Crawl Space

The average cost to add blown-in insulation to your crawl space ranges from $900 to $3,000. This assumes you are adding insulation to a depth of between 8” and 18”. Crawl spaces are common additions to the area around a finished top floor. They act as a small attic area and frequently contain storage space, ducts, and other utilities. They are insulated similarly to attic spaces. Because most already have some, you may only need a small layer blown in to bring them up to the recommended total.

Blow Insulation Into an Attic

The average cost to add blown-in insulation to your attic is $1,750 to $5,500. This assumes an attic of 1,500 sq.ft. Your costs could be different if your attic is larger or smaller. Attics need roughly 18” of insulation when complete to be considered fully insulated. Many have some insulation but not enough. Therefore, assume you add between 8” and 18” to most installations. Total depths vary depending on the climate and location.

Blow Insulation Into Walls

The cost to add blown-in insulation to exterior walls averages $2,000 to $4,000. This assumes an average thickness of 3” to 5”. Exterior walls are the most common areas for blown-in. This is because it is also one of the areas that tend to be under-insulated and where you see the biggest benefit. Thermal transfer through exterior walls is a home’s biggest source of energy loss. Insulating these areas makes a big difference in your space’s comfort and energy usage. Blown-in is the least invasive way to insulate this area, making it one of the most common types.

Pros and Cons of Blown-In Insulation

Blown-in is an easy way to add insulation to wall cavities, attic floors, crawlspaces, and other hard-to-reach areas. This is one of the least invasive ways to add insulation to existing walls. It is also less expensive than adding spray foam insulation to the same areas.

Blown-in insulation comes in several materials, all of which are generally healthier than spray foam, which emits high levels of VOCs. Blown-in can also be produced from recycled material, making it a green option for many projects.

Cellulose insulation used in walls settles over time, meaning you may need to add additional insulation. Cellulose also absorbs moisture, becoming heavy and soggy. This can be a problem when used on attic floors.

Blown-in cannot be used everywhere. It cannot cover a roof deck because it does not stay in place. This makes options like spray foam or batt insulation a better fit for some areas.

It is also time-consuming to install. While it can be done DIY, it has a steep learning curve that can cause issues with certain cavities not being completely filled.

How Long Does Blown-In Insulation Last?

Blown-in insulation lasts roughly 20 to 30 years under the right circumstances. This means the material is not disturbed by contractors or pests and has not absorbed moisture. Some materials last longer than others. Fiberglass starts shredding and settling the earliest, while rockwool lasts the longest without settling. The area size, moisture levels, and if the area has been disturbed factor into how long it lasts. If yours is older, you may want to have it inspected to determine its condition.

Blow-In Insulation Machine Rental

Some blown-in insulation is designed to be easier for those who want to DIY. To do this, rent the machine that feeds the material into the walls or cavities. You can usually find these rental machines at your local big box store. Rates vary by region, but most have a cost of around $125 a day to rent. You may get a discount for renting it for longer, and some stores have half-day rates if you only need it for a few hours.

Many stores offer a free tutorial on how to operate the machine. Ask before picking it up if you need a tutorial to learn how to operate it.

Fiberglass vs Cellulose Blown Insulation

Two of the most common materials used in blown-in insulation are fiberglass and cellulose. Fiberglass is made from fibers coated in spun glass, while cellulose is made from pulp, usually recycled paper. Of the two, only damp or wet spray cellulose works in wall cavities. Fiberglass is slightly less expensive, naturally flame-retardant, and not bothered by moisture. It is slightly less effective at insulating, though, with an R-value of 2.5 to 3.5 per inch. Cellulose must be treated to be flame-retardant and can be impacted by moisture. It does a better job of insulating with an R-value of 3.2 to 3.7 per inch.

| Material | Average Costs per Sq.Ft. (Installed) |

| Fiberglass | $1.65 - $2.60 |

| Cellulose | $1.75 - $3.80 |

Blown-In Insulation vs Batts

In addition to blown-in insulation, another method for insulating your home is to use batts. Batts are long pieces of rolls of insulating material, usually with some type of paper or foil backing material. Batts are less expensive than blown-in, but they take more work to install. They are the most common material for insulating cavity walls in a new home and the most common method of insulation for DIY homeowners.

Batts come in several materials, including fiberglass, rockwool, sheep wool, cotton, and some synthetic materials. You may find a cellulose batt, but this material is generally used for loose-fill only. Batts come in a range of R-values, depending on their thickness. They take the guesswork out of insulating because you get the exact R-value by purchasing the right thickness, meaning no measuring or adding. Batts can last as long as loose-fill and, in some cases, last longer, depending on the material.

| Material | Average Costs per Sq.Ft. (Installed) |

| Batts | $0.65 - $2 |

| Blown-In | $1.65 - $3.80 |

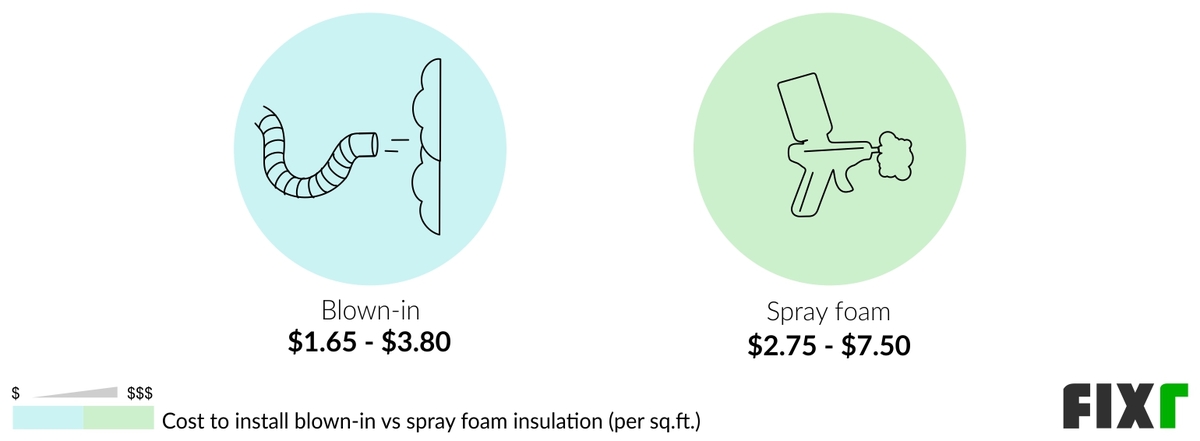

Foam vs Blown-In Insulation

Another good option for adding insulation to your home is foam. Foam is also sprayed into cavities. Unlike blown-in, which is loose, spray foam is a chemical liquid that expands on contact. It does a better job of insulating than batts or loose fill. It can also last longer because it is not as impacted by things like pests or moisture. However, it costs significantly more and is difficult to add to existing spaces. It is also not DIY-friendly and has a significant learning curve.

Spray foam comes in several types and materials. Some may give off high levels of VOCs, meaning it is not considered as green an option as loose-fill in most instances.

| Material | Average Costs per Sq.Ft. (Installed) |

| Blown-In | $1.65 - $3.80 |

| Spray Foam | $2.75 - $7.50 |

Enhancement and Improvement Costs

Soundproofing

Adding insulation to your home can improve the acoustics and add some soundproofing. You can also add acoustic-absorbing panels or materials to your home’s interior if you want to take it a step further. This costs roughly $10 to $30 a square foot.

Weatherstripping

Adding insulation lowers your energy costs. Improving your weatherstripping can also help. Weatherstripping seals gaps around your windows and doors, which can stop energy transfer. The average cost to weatherstrip a home is $200 to $600.

Mold Remediation

Sometimes, you may need to replace your existing insulation due to mold. If this is the case, you should have mold remediation done before you add new insulation. The average cost to remove the mold ranges from $1,500 to $3,500.

Additional Considerations and Costs

- Home value. Adding insulation to your home increases your home’s value. This is mostly due to the projected energy savings that a well-insulated home has. It can be difficult to get an exact cost breakdown.

- Dust. Loose-fill cellulose may be dusty unless you are specifically using a low-dust brand. For this reason, you may want to take steps to close off other spaces to contain the dust during installation.

- Hazardous material. If your home currently has mold or asbestos where you want to insulate, these must be removed first. If this is the case, your overall costs may be much higher.

FAQs

- How much does it cost to have insulation blown in?

The total cost depends on several factors, including the insulation type, thickness, and location. Average costs range from $1.65 to $3.80 a square foot.

- How much does it cost to install blown-in insulation in a 1,500 square foot house?

Many cost factors impact your final costs. You may not insulate every area in the home, and some areas may require more insulation than others. Costs range from $2,475 to $5,700.

- How many square feet does a bag of blown insulation cover?

Most bags contain roughly 40 sq.ft. of insulation. However, things like depth can make a bag cover more or less space.

- Can you do blown insulation yourself?

You can, but it is not always recommended. You can rent a blower from most big box stores and receive a tutorial on how it works. This is a time-consuming project, so many people choose to hire the pros.

- Can blown insulation be spread by hand?

You can touch it and move it by hand without harm. However, it is not designed to be spread or installed this way. Doing so can mean you miss areas or spread it too thin or thick for the area.

- Does cellulose insulation burn?

Cellulose insulation must be treated with flame-retardant chemicals to pass safety inspections. While the untreated material it is made from can burn, the material you install in your home is flame-retardant.

References

- Bob Vila. “5 Things to Know About Blown-in Insulation."

https://www.bobvila.com/articles/blown-in-insulation/ - Craftsman Book Company. National Construction Estimator, 69th ed., Ed. by Richard Pray (Carlsbad, CA, 2021).

- Energy Efficiency for All (EEFA). “A Guide to Healthier Upgrade Materials."

https://assets.ctfassets.net/ntcn17ss1ow9/3Bw3JFqYHgI7xWcvb7unwN/ec90d476bc2fd1315fb018eeeb467978/NRDC-3084_Guide_to_Healthier_Retrofit_Hi-res_smaller.pdf - Energy.gov. “Types of Insulation.”

https://www.energy.gov/energysaver/types-insulation - FIXR Cost Guides and Cost Database."

- Fixr.com. “Comparing the Health and Cost of Common Insulations in One Graph."

https://www.fixr.com/blog/2019/08/08/comparing-the-health-and-cost-of-common-insulations-in-one-graph/ - Retrofoam. “Who Are the Best Cellulose Insulation Manufacturers?"

https://www.retrofoamofmichigan.com/blog/best-cellulose-insulation-manufacturers - The Home Depot. “Owens Corning AttiCat Insulation Blower."

https://www.homedepot.com/p/rental/Owens-Corning-AttiCat-Insulation-Blower-AttiCat/315026895 - The Spruce. “Blow-In Insulation: The Basics.”

https://www.thespruce.com/blowing-in-insulation-vs-rolling-out-fiberglass-1821913 - The Spruce. “What You Should Know About Blow-In Cellulose Insulation."

https://www.thespruce.com/cellulose-insulation-basics-1821904